Virtual sailing

- Ollie Skelton

- Apr 3, 2018

- 3 min read

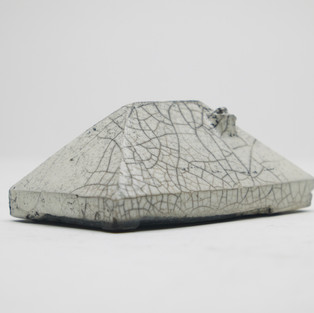

I like how the boats Ive produced so far have been going, however for the final show i want to produce a lot of them which realistically is going to require casting. If I'm going to cast I thought that I might as well make the boats as pristine and symmetrical as possible, and the best way (for me) to do that would be to model the boats in CAD, 3D print them and then use the prints as mould blanks. I've done this process before for a previous project where I made rooves and it works really well, however they were a much less complex geometry to model and print so moving up to making boats will be a challenge. Below you can see my 3D printed roof while it was being sanded smooth on the left and then the final casts after being raku glazed. as you can see the corners are really sharp and clean and just way way better than I would've been able to do by hand.

I've some experience with Autodesk fusion 360 (a computer aided design package made by Autodesk which is free to use for students and hobbyists, and has most of the capabilities of their professional engineering software) already having used it for multiple projects during A-level and foundation as well as a lot of pissing around instead of doing revision, however the hull of a ship involves a very complex compound curved face which I had no idea how to make. I consulted the book of youtube to try and find a tutorial video that could walk me through how to create such a shape and low and behold the perfect video exists. This tutorial* teaches you how to make a very detailed model of a wooden boat, including all the sections of the frame and the fasteners and everything, which I didn't need to know all of, however it did teach me how to make the compound curved faces which i could then apply to my own designs.

speaking of my own designs I made three. The first one was very small and slim and in the end I decided that that one was just too weedy so scrapped it. i then made a similar one but a bit bigger and also with a more rounded profile (from a straight ahead view) as just like in my clay boats I'd made my first one too triangular. I then made another boat which was slightly wider and longer but also much taller so that theres contrast in my casts when they're displayed and they don't all look the same.

Above is the 'engineering' drawing of my first CAD boat. I find it extremely useful to print out drawings like these on paper at a 1:1 scale so I can really see the actual size instead of having to imagine it. on this model for example id thought that 5mm was a good thickness for the rim and keel of the boat when i was making the model, however when i printed it off i realised how thin 5mm actually is and that i would need to make it much thicker for aesthetic and practical purposes for my real cast.

The drawings below show the small and large boats that I will be 3D printing. I like that there's a big size different between these two boats and I think they compliment each other well. you can also see the difference between my two small boats and how the second one is slightly deeper and less pointy.

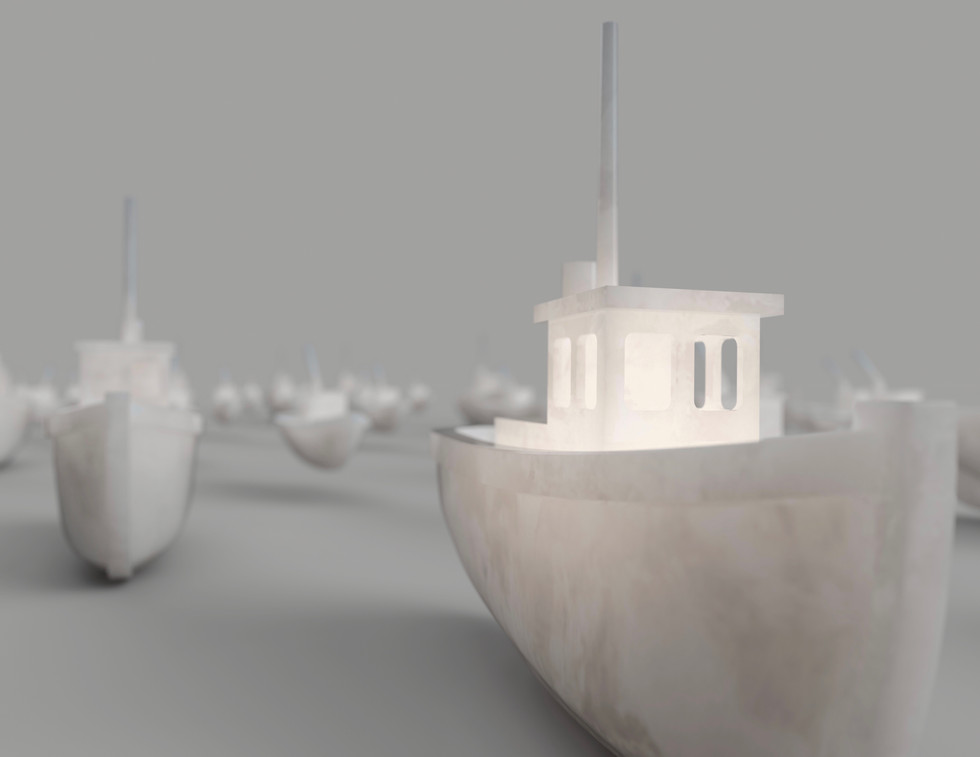

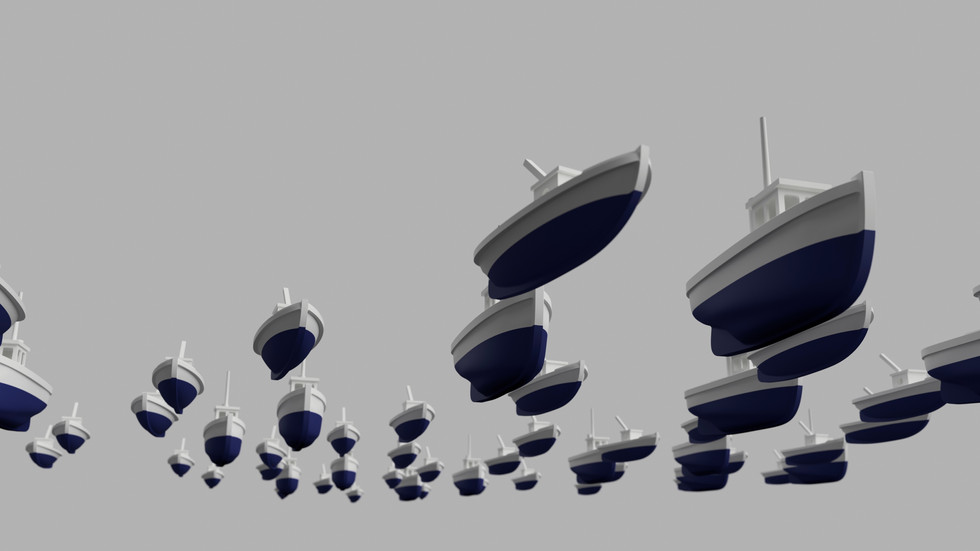

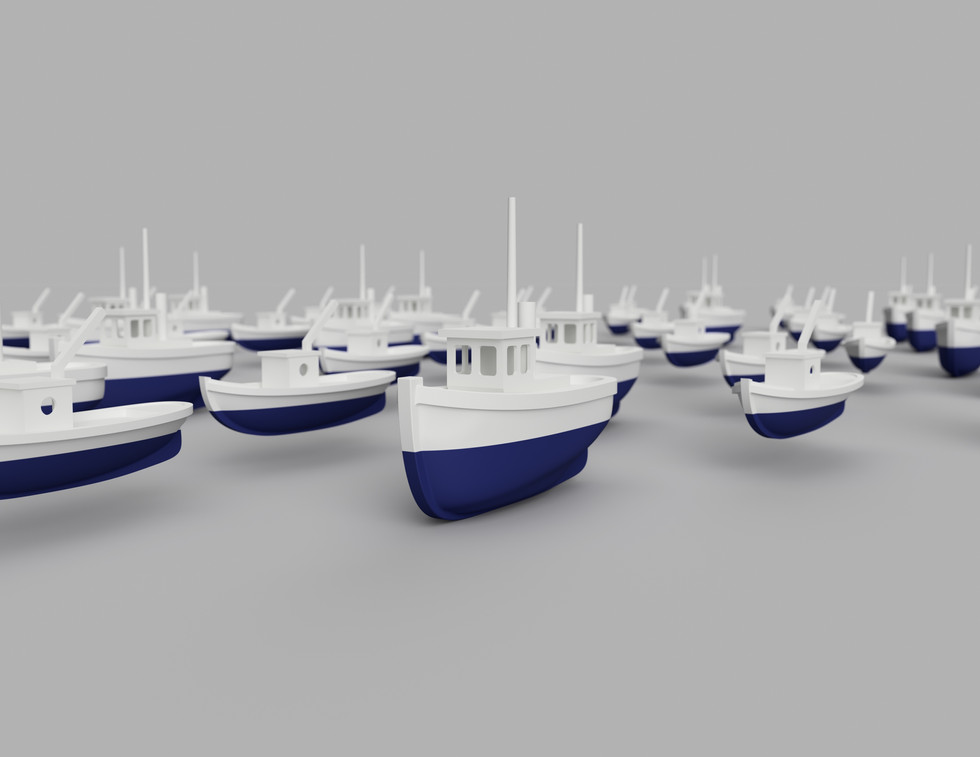

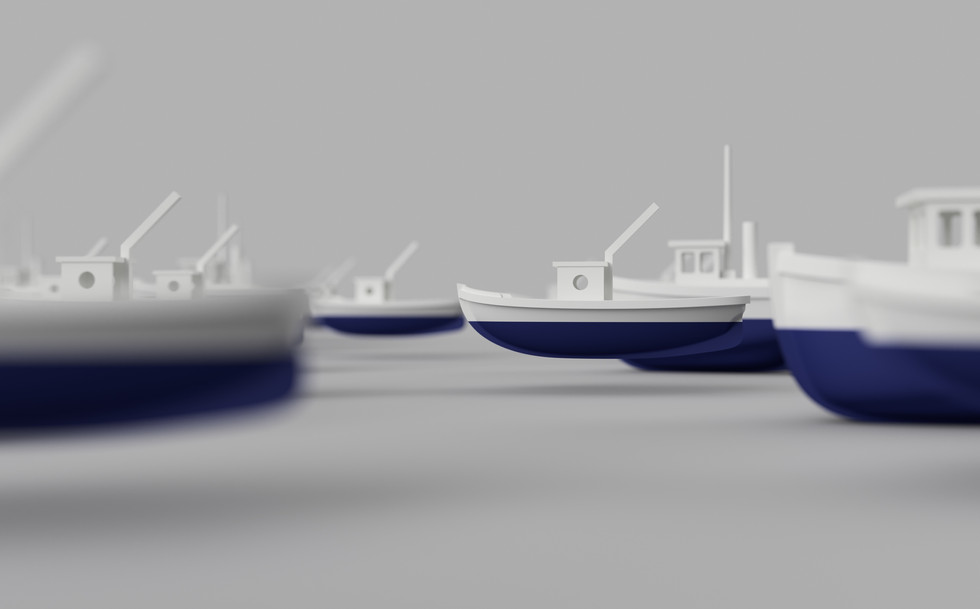

i rendered these boats in jade basically because it looks nice and vaguely looks like glazed ceramic (although actually not at all really). The rendering software built into fusion 360 is quite basic, and it can produce really professional looking results in certain materials on certain forms, and finding what looks real and what doesn't is mainly a process of trial and error. In this case I thought the jade looks really life like besides the fact the cabins are glowing in some images for no reason so chose to use that as my render material. I also created some images rendering in matte plastic which you will see lower down is not as lifelike and is devoid of texture which prevents it from looking real in my eyes. I also copied and pasted my models a lot of times to see what a whole fleet would look like and get an idea of how i might arrange all my casts for exhibition.

To create some more interest and texture on my boats i split them into two tones of colour, a white and a blue, where the water level would be. when i make these in really life i plan on dipping them in a blue glaze up to the same level and leaving the top bare.

*https://www.youtube.com/watch?v=ixGnJjNPj18&index=24&list=LLnIKvR7xolNz35qV752WUgQ&t=562s

Comments